SERVICES

Our comprehensive range of services covers every step of the fruit supply chain, from sorting and cleaning to coating, packaging, transportation, export, and distribution. We prioritize quality, freshness, and customer satisfaction to deliver the best possible fruit products to our clients worldwide.

SORTING PROCESS

We have a comprehensive fruit sortation system in place to separate the fruits based on their size, color, and quality.

CLEANING PROCESS

The fruits undergo a thorough cleaning process to remove any dirt, debris, or pesticides. We prioritize the use of environmentally friendly and safe cleaning methods.

COATING PROCESS

Our specialized coating technology is designed to enhance the shelf life of the fruits by providing a protective layer. This coating helps reduce spoilage, maintain freshness, and preserve the natural flavors and appearance of the fruits.

PACKAGING

The fruits are meticulously packaged using high-quality materials and techniques. Our packaging experts ensure that the packaging is durable and designed to minimize any damage during transportation.

CUSTOM DESIGN

We also provide custom carton box design to cater to the unique requirements of our clients.

TRUCKING

To ensure the fruits reach their destinations in optimal condition, we have a reliable transportation network with temperature-controlled vehicles.

STORAGE

Cold storage for fruits is a crucial aspect of preserving their quality, freshness, and extending their shelf life. We can provide cold storage services that cater to your fruit storage needs. Our facilities are designed to maintain optimal temperature and humidity levels, ensuring the fruits remain in the best possible condition.

LOLO (LOAD ON LOAD OFF)

Load on, Load off services play a crucial role in the global supply chain by ensuring smooth and secure transportation of goods in containers, connecting various modes of transportation and contributing to the seamless flow of trade across the world.

PLUG IN

Plug-in reefer containers play a crucial role in maintaining the quality and safety of perishable goods during transportation. They help reduce spoilage and waste, ensuring that products arrive at their destination in optimal condition. This, in turn, benefits both the shippers and consumers by reducing costs and ensuring a consistent supply of fresh and high-quality goods.

FUMIGATION

Fumigation as a plant quarantine treatment aims to

freeing the carrier media from insect pests, mites, nematodes, or

mollusk.

PHYTOSANITARY REPORT

The function of this document is to guarantee that the products being exported are free from mold, germs and bacteria.

HEALTH CERTIFICATE

Health Certificate (HC) is an official document clarifying that particular goods have met the destination country's regulations, health standards, and other requirements.

RADIATION CERTIFICATE

Some countries require, especially for food products, a certificate proving that they do not contain radioactive substances, before accepting the import and selling of such products in its territory. This presentation certifies that the products subject to the export or import are excluded from radioactivity.

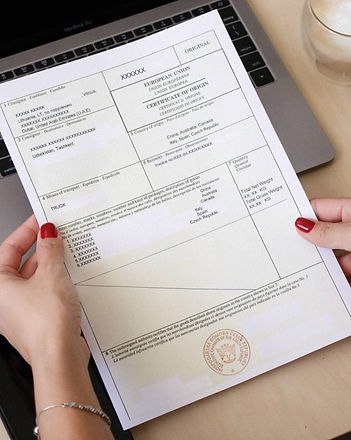

COUNTRY OF ORIGIN CERTIFICATE

A Certificate of Origin (CO) confirms the 'nationality' of a product and serves as a declaration to satisfy customs or trade requirements.

FULL COLOR PRINTING

Great Quality. Greater Prices.

Full-color printing packaging is a printing technique that allows for the reproduction of vibrant, detailed, and multi-colored designs on packaging materials. Unlike traditional printing methods that use limited colors or monotones, full-color printing utilizes a combination of four primary ink colors—cyan, magenta, yellow, and black (CMYK)—to create a broad spectrum of hues and shades.

Here's a breakdown of what full-color printing packaging entails:

1. **Vibrant Colors**: Full-color printing enables the reproduction of vivid and eye-catching colors, making packaging designs stand out on the shelves and grab consumers' attention.

2. **High-Quality Images**: It allows for the printing of high-resolution images with fine details and smooth color gradients. This is particularly beneficial for showcasing product photos or intricate artwork on packaging.

3. **Customization**: Full-color printing offers endless customization possibilities, allowing brands to create packaging designs tailored to their specific products, brand identity, and target audience. From bold graphics to intricate patterns, virtually any design concept can be brought to life.

4. **Brand Consistency**: Consistent use of colors and design elements across packaging helps reinforce brand recognition and build brand loyalty among consumers.

5. **Informational Content**: Full-color printing packaging isn't just about aesthetics—it also serves a functional purpose by conveying important product information, instructions, ingredients, and branding messages clearly and attractively.

6. **Materials**: Full-color printing can be applied to various packaging materials, including paperboard, corrugated cardboard, plastics, metal, and more, offering flexibility to accommodate different packaging needs and product types.

7. **Marketing Impact**: Packaging is often the first point of contact between consumers and a product. Full-color printing allows brands to leverage packaging as a powerful marketing tool, effectively communicating product benefits, values, and brand stories to consumers.

In summary, full-color printing packaging is a versatile and effective way for brands to create visually appealing, informative, and memorable packaging solutions that enhance product visibility, attract consumers' attention, and reinforce brand identity.

MANGOSTEEN CARTON BOX

RAMBUTAN CARTON BOX

PINEAPPLE CARTON BOX

SEEDLESS LEMON CARTON BOX

CALIFORNIA LEMON CARTON BOX

SILK PRINTING

great design that catches everyone attention

Silk printing packaging, also known as silk screen printing or screen printing, is a versatile printing technique commonly used for creating customized designs on various types of packaging materials. Unlike full-color printing, which utilizes the CMYK color model, silk printing typically involves the transfer of ink through a fine mesh screen onto the packaging substrate. Here's a detailed description of silk printing packaging:

1. **Process**: Silk printing involves the creation of a stencil (or screen) with the desired design, where areas to be printed are open and those to be left blank are blocked off. Ink is then applied to the screen, and a squeegee is used to push the ink through the mesh onto the packaging material. Each color in the design requires a separate screen, allowing for precise registration and layering of colors.

2. **Ink**: Silk printing typically uses specialty inks, including solvent-based, water-based, or UV-curable inks. These inks are chosen based on factors such as substrate material, desired finish, and environmental considerations.

3. **Design Flexibility**: Silk printing offers great flexibility in design, allowing for the reproduction of intricate details, bold graphics, and solid colors with precision. It's suitable for both simple and complex designs, making it ideal for packaging customization.

4. **Color Options**: While silk printing doesn't offer the same broad color range as full-color printing, it still provides a wide selection of standard and custom colors. Pantone matching systems (PMS) are often used to achieve precise color matching for brand consistency.

5. **Materials**: Silk printing can be applied to various packaging materials, including paper, cardboard, plastics, glass, metal, and fabrics. Its versatility makes it suitable for a wide range of packaging applications, from labels and boxes to bottles and containers.

6. **Durability**: Silk printing results in durable and long-lasting prints that resist fading, scratching, and abrasion. This makes it particularly suitable for packaging that undergoes handling, transportation, or exposure to environmental factors.

7. **Cost-Effectiveness**: Silk printing is often cost-effective for medium to large production runs, as the setup costs are relatively low compared to other printing methods. It's a preferred choice for bulk orders and repetitive designs.

In summary, silk printing packaging offers a blend of versatility, durability, and cost-effectiveness, making it a popular choice for brands looking to customize their packaging with high-quality designs that enhance product visibility and appeal.

DRAGON FRUIT SILK PRINTING PACKAGING

Single Wall Kraft Paper

MANGGO SILK PRINTING PACKAGING

Single wall kraft paper

PINEAPPLE SILK PRINTING PACKAGING

Double Wall Kraft Paper

MANGOSTEEN SILK PRINTING PACKAGING

double wall kraft paper

MANGOSTEEN SLIK PRINTING PACKAGING

single wall kraft paper

BANANA AND PINEAPPLE SILK PRINTING PACKAGING

double wall kraft paper